How to map the knowledge "sticking points"

Knowledge transfer often requires several steps, and knowledge can get stuck along the way. But where are those sticky points?

I have often used the analogy of a Supply Chain when looking at knowledge transfer, with knowledge as a resource to be supplied to the knowledge workers on whose decisions the firm depends, in order to support them in making the best available decisions.

That knowledge supply chain can be very simple, in the case (for example) of a supervisor coaching their staff. Or it can be complex, as in the case of organisational lesson learning. Where the supply chain is complex, involving many steps. it can be all too easy for the knowledge to get stuck or to run into quicksand along the way; never to reach the knowledge worker.

If we can map out the supply chain, we can find the sticking points, and un-stick the knowledge.

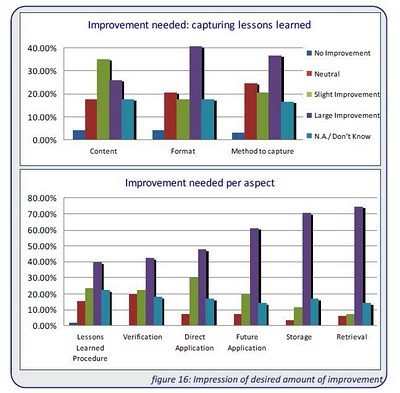

The figure here is reproduced with permission from a thesis dissertation by Catherine Barney, entitled “Cross-project learning in project-based organizations”, and Catherine did just this exercise of mapping the knowledge supply chain.

Catherine was studying knowledge management and lesson-learning in a major European engineering company. As part of her dissertation, Catherine surveyed the company to measure employees’ satisfaction with various steps (or “aspects”) in the lessons learned cycle (an important component of the knowledge supply chain for this global organisation).

She mapped the chain as having 6 components

- Lesson identification through the lessons procedure

- Lesson validation

- Direct application of lessons

- Future application of lessons

- Lesson storage

- Lesson retrieval

Her lower diagram (above) is interesting. Every step of the process seemed to need significant improvement, but this need was smallest with the first step – lesson identification – and indeed the content of captured lessons showed the highest level of satisfaction. With every step after that, dissatisfaction grows. This could either be because this company (like many others) thinks the job is done once the lesson is “captured”, or because inefficiencies along the chain combine to make each step progressively less satisfactory (in other words, poor verification on top of poor capture leads to even less satisfaction with application).

It looks like lessons are entering the chain, but getting lost or stuck as they go along. If this company wants to improve their lesson supply chain, they need to focus not so much on lesson capture and validation, but what happens to the lessons afterwards, and how they are re-used.

Contact us for help in mapping the sticking points in your lessons chain.

Tags: Archive

Leave a Reply